Blood flow model

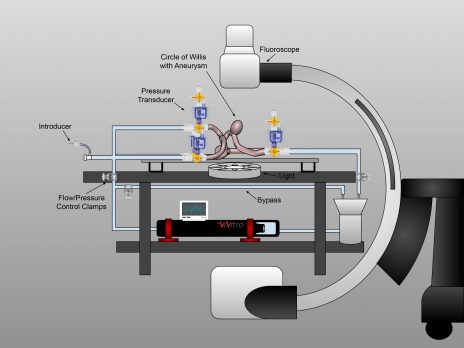

A ViVitro programmable pump is used to simulate human blood flow from the heart and pump BDL analog (a viscosity-matched, shear-thinning blood substitute) throughout the system. This comprehensive flow system uses physiologically matched interchangeable 3D printed neurovascular, cardiovascular, or peripheral vessel models with real time pressure measurements in each branch.

- Advanced in vitro flow system: Our team utilizes the BDL’s digitally controlled, programmable hydraulic pump system (SuperPump AR, ViVitro Labs) that simulates physiological cardiovascular, peripheral, or neurovascular flows. Interchangeable, 3D-printed, vessel-like models connected in-line with the flow system for specific device testing.

- In vitro circle of Willis (CW) model design: The in vitro vessel model, 3D-printed from soft UV-cured polymers (PolyJet process), has similar mechanical properties to human tissue.

- Proximal and distal branches of the model are fitted with valves and pressure transducers for real-time pressure and flow during aneurysm treatment or aspiration/mechanical thrombectomy monitoring

- The pressure transducers are connected to a 16-channel NI 9239 Data Acquisition (DAQ) module and displayed in LabVIEW®

- Catheters are introduced into the CW model following standard interventional surgical techniques (on the bench and under fluoroscopic guidance)

- Real-time pressures during catheter placement, clot integration, and clot digestion are recorded with precise time stamps.

- Cardiovascular and peripheral-vascular models: Readily available and can be quickly and accurately developed in conjunction with collaborators’ needs.