Medical device testing

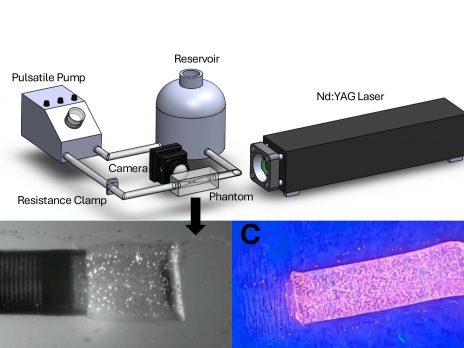

PIV imaging and CFD modeling

- State of the art particle imaging velocimetry (PIV) incorporates fluorescent microparticles into blood flow models (A) for analyzing clot ingestion stresses, strains, forces and velocities via modern aspiration catheters (B) using synthetic blood clots (C) mechanically-matched to the mechanical properties of human “hard” and “soft” clots.

Certified and validated custom testing setups

- We can design and validate testing setups for custom medical device and model analysis by combing our available engineering expertise resources: such as 3D-prototyping, mechanical testing, surgical suite simulations, cleanroom manufacture, and device finishing resources

Device, model, biological tissue material and mechanical testing

- Rheometer modulus and strength testing (see DMA-Rheometer)

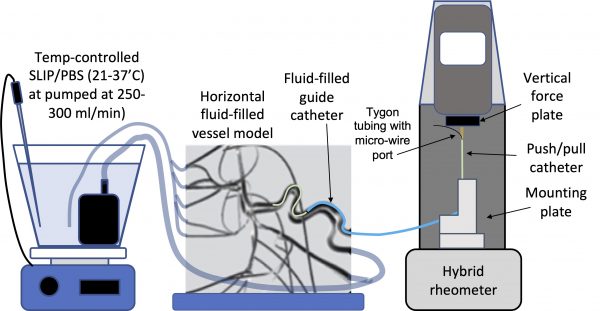

Catheter flexibility testing

- catheter inflection force at all lengths/transitions along the catheter shaft

- good indicator of catheters effectiveness with push force, torque-ability, and flexibility along its usable length

Surface tension testing

- Surface tension helps determine how well a fluid interacts with itself versus disassociating into its surrounding environment.

- Fluids that freely dissociate typically form highly lubricious interactions with surfaces, such as catheters and vessel models

Annealing/heat-set oven

- Prototyping catheter, stent, and braided wire devices for heat setting final shapes

- 10 x 6 x 6 inch oven for polymer jacket heating, nitinol wire annealing and modifying transition temperatures, from 20 to 2000 °C

Push-pull catheter-vessel friction testing

- Established lubricity for human and animal vessel

- Compare silicone vessel models, 3D-print vessel models, and glass vessel models